Glass Forming

Glass forming is the process of using heat and manipulation of glass tubing and rod to create a range of products with multiple applications across a variety of industries. We have the facility to form using borosilicate heat resisting tubes and rods as well as Quartz glass tubes; which can resist temperatures up to 1200°C.

Technical Glass

Examples of products that can be produced by forming include flanged glass tubes for use in lining metal pipes in chemical laboratories, and for heat exchangers. Condensing coils, glass U bends, glass straws, laboratory ware, flow indicator tubes, and glass droppers. The creation of blown vessels, cones, funnels to specific sizes. You can see further examples ibn the side show below. These are only a few examples please contact us with your specific requirements.

Lighting Glass

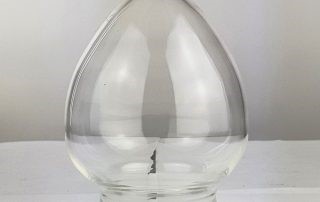

A very popular application of glass forming is in the preparation of light shades either from both standard glass tubing, or from the Conturax range of tubing shapes. You can create unique forms in styles only limited by your imagination.

The advantages of using tubing as the glass source means that the finished article are free from streak and bubbles, that can be a concern when using traditional glass blowing methods. The minimum order quantities also tend to be lower when choosing glass forming over traditional glass blowing methods A few examples of the shades that can be produced are given in the slide show below. These are only a few examples please contact us with your specific requirements.

Decorative Glass

Decorative glass features covers a multitude of products from glass ornaments, Christmas baubles, oil burners for restaurants, trough to large decorative forms from either standard plain or ribbed glass tubes. A few examples are given in the slide show below.

Quartz Glass

Quartz Glass has special properties that lend itself to the forming of products, principally for technical applications. Your can find out more about the products available on Quartz Glass Tubing page and our more general Quartz Glass page.

The principal benefit is that quartz can resist temperatures up to 1200°C, it can be heated and formed into envelopes for high temperature lights, condensing coils, quartz boats and vessels, u-bends and similar. You can see a few examples of the products produced in the slide show below.