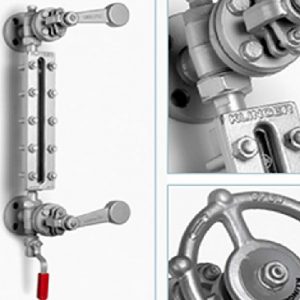

Process Level Gauges

Process Level Gauge - Reflex

SKU: Process Level Gauge - Reflex

Reflex Level Gauge is available in the range ANSI Class 150 to ANSI Class 1500, it is particularly suited for low pressure steam boilers, gas liquefaction plants, reactors or storage vessels.The Refl...

Process Level Gauge - Transparent

SKU: Process Level Gauge - Transparent

Transparent Level Gauge is perfectly suited for viscous, interface and coloured liquids.With two pieces of glass on opposite sides of the chamber, light passes through the transparent level gauge allo...

Process Level Gauge - Illuminators

SKU: Process Level Gauge - Illuminators

EEx rating according to type of lamp used. Supplied with aluminium housing for corrosive applications A light diffuser is mounted to concentrate the light onto the level gauge Voltage 110-230V AC (max...

Process Level Gauge - Valves & Cocks

SKU: Process Level Gauge - Valves & Cocks

There are two types of shut off devices - RAV gauge valves and DG gauge cocks. RAV gauge valves have metal seats and an integrated safety ball. The DG gauge cock is a more economical solution for simp...

Packing Sleeves

SKU: Packing Sleeves

Boiler packing sleeves are essential components in industrial boilers, designed to provide efficient sealing and prevent leakage around the boiler's tubes. Our Packing Sleeves are made from 99.5...

John Moncrieff is a leading provider of high-quality process level gauges designed to deliver precise and reliable measurements in a wide range of industrial applications. Our gauges are engineered for accuracy, durability, and ease of use, ensuring optimal process control and efficiency.

Key Features of Our Process Level Gauges:

- Precision Measurement: Our gauges offer accurate and consistent level readings, even in challenging environments.

- Durable Construction: Built to withstand the rigors of industrial operations, ensuring long-lasting performance.

- Customisable Options: Choose from a variety of gauge types, materials, and configurations to meet your specific requirements.

- Easy Integration: Our gauges are designed for seamless integration into your existing process control systems