Steam Level Gauges

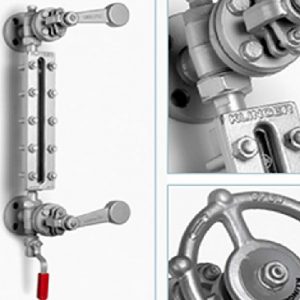

Steam Level Gauge - Reflex

SKU: Steam Level Gauge - Reflex

Reflex Level Gauge is available in the range ANSI Class 150 to ANSI Class 1500, it is particularly suited for low pressure steam boilers, gas liquefaction plants, reactors or storage vessels.The Refl...

Steam Level Gauge - Transparent

SKU: Steam Level Gauge - Transparent

Transparent Level Gauge is perfectly suited for viscous, interface and coloured liquids.With two pieces of glass on opposite sides of the chamber, light passes through the transparent level gauge allo...

Steam Level Gauge - Bi-Colour

SKU: Steam Level Gauge - Bi-Colour

Bi-colour steam level gauge is suitable for high pressure boilers up to 210 bar saturated steam. With a clear red and green liquid and steam reading level indicator, the gauge provides accurate and re...

Steam Level Gauge - Accessories

SKU: Steam Level Gauge - Accessories

A range of accessories are produced for steam level gauges including illuminators, gauge glasses, micas, shields, gaskets, engraved scales and various other components. Read through the product detail...

Packing Sleeves

SKU: Packing Sleeves

Boiler packing sleeves are essential components in industrial boilers, designed to provide efficient sealing and prevent leakage around the boiler's tubes. Our Packing Sleeves are made from 99.5...

John Moncrieff is a trusted supplier of high-quality steam level gauge products designed to meet the rigorous demands of industrial applications. Our extensive range includes a variety of gauges, accessories, and components to ensure accurate and reliable monitoring of steam levels in boilers, turbines, and other critical systems.

Key Features of Our Steam Level Gauge Products:

- Precision Engineering: Our gauges are meticulously crafted for precise and consistent measurements.

- Durable Construction: Built to withstand the harsh conditions of steam environments, including high temperatures and pressures.

- Safety Features: Equipped with safety devices to prevent accidents and ensure operator protection.