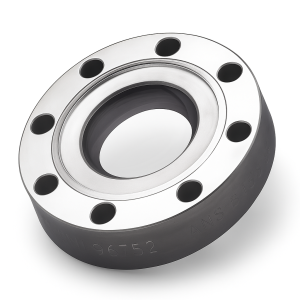

METAGLAS® Sight Glass Solutions for Vacuum & Special Applications

METAGLAS® sight glasses deliver world-leading safety, clarity, and reliability across the most demanding

operating environments. Whether installed on ultra-high vacuum systems or specialised hygienic and

chemical-processing equipment, METAGLAS® sets the benchmark for performance through its mechanically prestressed,

fused-metal construction.

METAGLAS® Sight Glass – Vacuum Applications

Designed for high vacuum and ultra-high vacuum (UHV) environments, METAGLAS® vacuum-rated assemblies

offer exceptional sealing integrity, minimal outgassing, and superior mechanical strength.

The fused-metal construction eliminates the risk of catastrophic fracture, making them ideal for critical

scientific and industrial vacuum systems.

Key Advantages

- Exceptional vacuum integrity — suitable for high vacuum and UHV service

- Zero-rupture design ensuring highest operational safety

- Ultra-low outgassing for contamination-sensitive environments

- Compact, low-profile construction ideal for tight vacuum systems

- Thermally stable for vacuum bake-out and temperature cycling

- Long service life with outstanding resistance to shock and fatigue

Typical Vacuum Applications

- UHV research chambers

- Semiconductor and thin-film processing

- Plasma and ion-beam systems

- Cryogenic and thermal vacuum installations

- Analytical instruments and particle detection equipment

- High-purity laboratory and cleanroom processes

METAGLAS® Sight Glass – Special Applications

METAGLAS® can be adapted for chemical, pharmaceutical, hygienic, and high-temperature environments where

conventional sight glasses fail. Its prestressed construction delivers unmatched strength, while polished, flush

surfaces support sanitary and aseptic operation.

Engineered for Challenging Environments

- Chemical resistance for aggressive media

- Aseptic & sterile duty designs for CIP/SIP processing

- Explosion-proof configurations with integrated EX lighting

- High-temperature capability with exceptional thermal cycling stability

- High-pressure compatibility for severe process conditions

- Custom geometries including rectangular, D-ended, and specialty formats

Industries Served

- Pharmaceutical and biotech

- Food and beverage production

- Chemical and petrochemical processing

- Power generation and energy systems

- Sanitary, sterile, and hygienic applications

- OEM process equipment and custom machinery

Why Choose METAGLAS®?

- Highest mechanical strength of any sight glass technology

- Unmatched safety through mechanical prestressing

- Ideal for regulated industries requiring validation

- Engineered for cleanability, sterility, and long operational life

METAGLAS® delivers unrivalled performance where visibility, safety, and cleanliness are non-negotiable.

From vacuum chambers to sterile pharmaceutical processes, METAGLAS® ensures total reliability backed by

decades of proven global use.