Quartz Laser Drilling

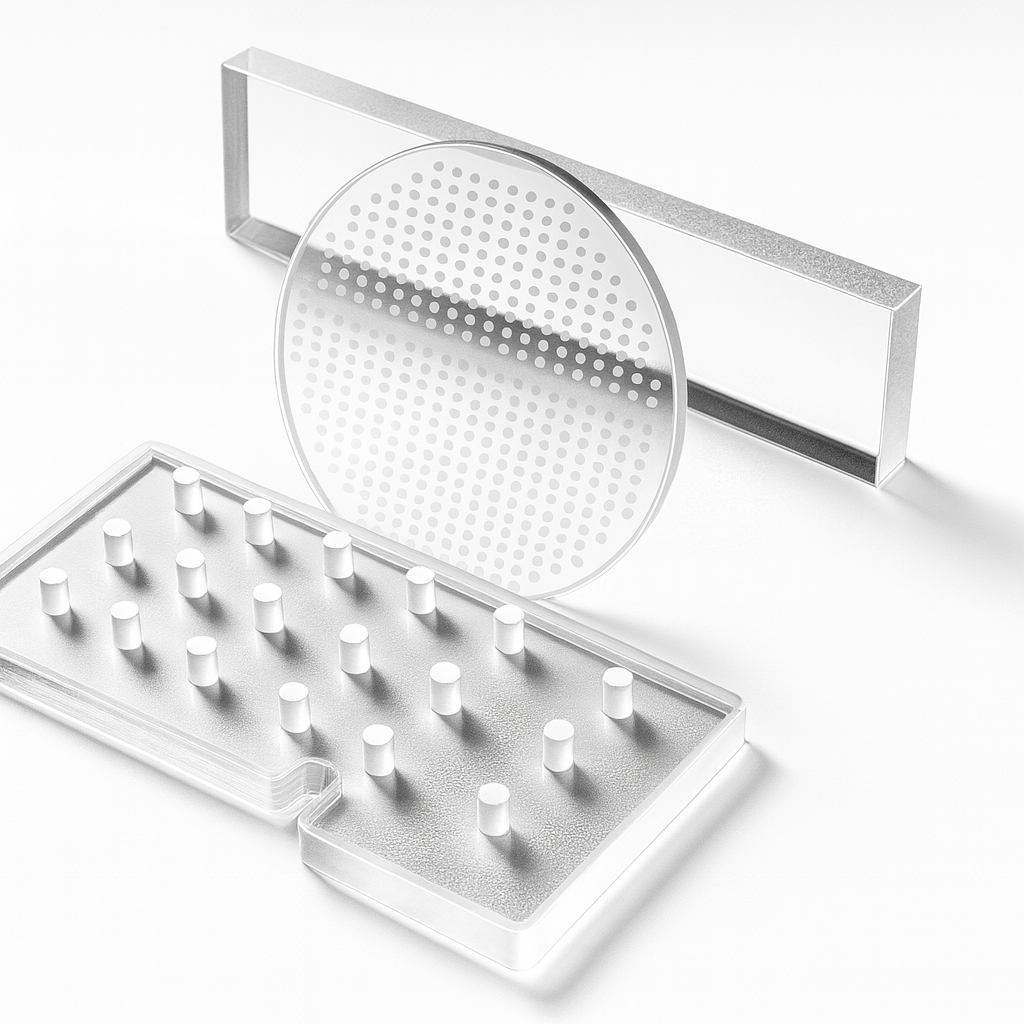

Quartz Laser Drilling Services — Micron-Scale Accuracy, Industrial-Grade Throughput

Transform your industrial applications with John Moncrieff Ltd’s state-of-the-art quartz laser drilling. When microscopic precision meets industrial strength, possibilities multiply. Leveraging next-generation laser systems, tooling control, and in-process metrology, we deliver unrivalled accuracy and repeatability in precision drilling for fused silica and quartz components.

Core Capabilities

- Ultra-Fine Holes: Down to Ø 0.05 mm (50 µm) nominal.

- Thickness Envelope: From 0.03 mm thin stock up to 10 mm.

- Dimensional Precision: Feature tolerance to ±0.015 mm (process-dependent).

- Working Area: Parts and panels up to 1,500 mm in length.

- Geometry Control: Low-taper bores, countersinks, blind holes, and through-vias.

- Array Processing: High-density patterns for microfluidics, filters, and nozzle plates.

- Edge Quality: Clean exits with post-polish options for optical-grade finishes.

Applications

- Semiconductor & Microfluidics: Via arrays, capillaries, and wafer-level features.

- Optics & Photonics: Precision apertures, pinholes, and alignment features.

- Sensing & Analytics: Flow cells, probe ports, and micro-orifices.

- Process Windows: High-temperature, chemically resistant viewports with engineered vents.

- Scientific Instrumentation: Custom manifolds, nozzle plates, and jetting components.

Technical Envelope

- Materials: High-purity fused silica / synthetic quartz (>99.99% SiO₂), JGS1/JGS2/JGS3 equivalents.

- Feature Density: Tight-pitch hole arrays with controlled spacing and uniformity.

- Thermal Management: Pulse-tailoring to minimise micro-cracking and heat-affected zone.

- Flatness & Fixturing: Precision clamping for low-bow panels and thin sheets.

- Secondary Ops: Chamfering, bevels, countersinks, and optical-edge polishing on request.

Quality & Compliance

- ISO 9001: BSI-audited quality system with full material traceability.

- In-Process Metrology: CMM / digital vision inspection and SPC reporting.

- Documentation: Dimensional reports, CoCs, and bespoke QA plans available.

- Clean Handling: Clean-area packaging and optional Class 1000 protocols.

- Double QC: Incoming and final inspection to lock in repeatability