Quartz Glass Processing & Quality Control

Quartz CNC Processing

View Products

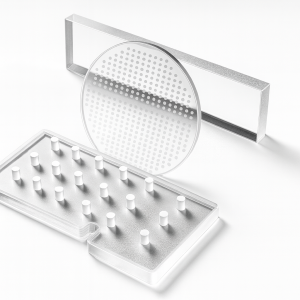

Quartz Laser Drilling

View Products

Quartz Equipment & Capabilities

View Products

Quartz Glass Quality Control & Inspection

View ProductsQuartz Glass Quality Control: Ensuring Absolute Integrity

At John Moncrieff, we don’t just make quartz components — we guarantee their performance. Our rigorous quality control framework ensures every piece meets the structural, optical, and chemical standards demanded by leading-edge applications.

Material Purity & Chemical Analysis

- High-Purity Verification: Analytical testing to confirm ≥ 99.99% SiO₂ content.

- Trace Impurity Screening: ICP / spectrochemical assays to detect contaminants.

- Chemical Stability Tests: Exposure to acid / alkali atmospheres to validate corrosion resistance.

Dimensional & Geometric Certification

- Tolerance Checking: Precise measurement of thickness, diameter, flatness, concentricity.

- Surface Flatness & Parallelism: Interferometry and optical flat references for critical optics.

- Edge & Corner Inspection: Microscope assessment of bevels, chips, and edge quality.

Optical & Transmission Performance

- Light Transmission Testing: UV-VIS-IR spectrophotometry across target wavelengths.

- Scatter & Haze Evaluation: Quantification of stray light and surface scattering.

- Refractive Index Uniformity: Monitoring for gradient or inhomogeneity.

Thermal & Mechanical Integrity

- Thermal Shock Resistance: Controlled cycles of heating / cooling to validate robustness.

- Mechanical Strength Testing: Biaxial bending, fracture testing as required.

- Stress Birefringence Analysis: Polariscopic inspection to identify internal stress zones.

Our quality control records and certificates are traceable and auditable. Should you require ISO certificates, material test reports (MTRs), or batch-specific documentation, our team will furnish them on request.