Quartz Glass Explained

Quart Glass JGS 1 - Ultra High Purity Synthetic

SKU: Quartz Glass - JGS1

JGS1 Quartz Glass: Ultra-High Purity Synthetic Fused Silica JGS1 quartz glass is a premium synthetic fused silica produced using SiCl4 as the raw material and melted with a...

Quartz Glass JGS2 - Professional Grade Natural Quartz

SKU: Quartz Glass - JGS2

JGS2 Quartz Glass: Professional-Grade Natural Fused Silica JGS2 quartz glass is a professional-grade natural fused silica produced by refining high-purity natural quartz cr...

Quartz Glass JGS3 - Advanced Infrared - Optimised Quartz

SKU: Quartz Glass - JGS3

JGS3 Quartz Glass: Advanced Infrared-Optimised Fused Silica JGS3 quartz glass is an advanced grade of fused silica designed for optical systems requiring broad spectral tra...

Quartz Glass Types: Properties, Grades & Applications

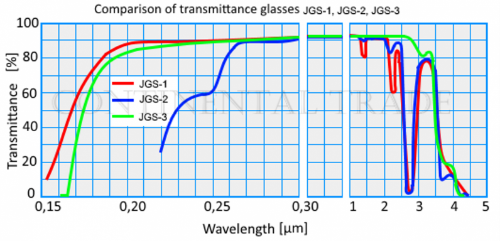

There are three main types of quartz glass, each with its own distinct performance profile. In addition, various proprietary brands offer tailored properties for specific technical demands. John Moncrieff Ltd is unique in its ability to process both standard quartz materials and brand-specific grades — giving our clients full flexibility in design and performance.

The following summary outlines the primary fused silica types, their properties, and common applications.

Fused Silica Types: A Comparative Overview

Fused silica — a critical material in optical and industrial systems — varies significantly depending on manufacturing method and purity. Key differences lie in hydroxyl (OH) content and ultraviolet (UV) transmission, both of which determine its suitability for specific uses.

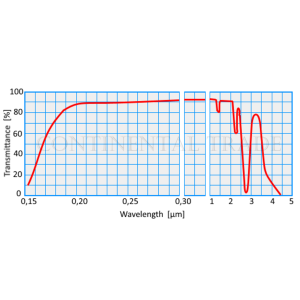

JGS1 – Ultra-High Purity Synthetic Quartz

- High OH content (~2000 ppm) with exceptional deep-UV transmission down to 185 nm.

- Ideal for deep-UV applications, excimer lasers, and precision optical lenses.

- Equivalent brands: Heraeus Suprasil 1/2, Corning 7980, Dynasil 1100 / 4100.

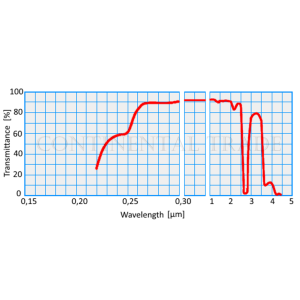

JGS2 – Professional Grade Natural Quartz

- Lower OH content (100–200 ppm) with excellent UV and visible transmission.

- Suitable for general UV/visible optics and high-temperature industrial systems.

- Equivalent brands: Heraeus Homosil, Dynasil 1000 / 4000 / 5000 / 6000.

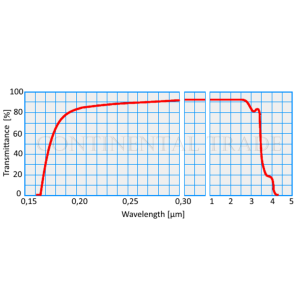

JGS3 – Advanced Infrared-Optimised Quartz

- Minimised OH content for broadband transmission from deep-UV through mid-IR.

- Ideal for wide-band optical systems and high-temperature IR applications.

- Equivalent brands: Heraeus Suprasil 300.

Key Considerations for Material Selection

- Purity: Trace impurities and defects directly affect optical transmission and fluorescence.

- Thermal Stability: Fused silica’s ultra-low thermal expansion ensures exceptional dimensional stability.

- Mechanical Properties: High hardness with inherent brittleness — handle with precision.

- Cost Factors: JGS1 is the highest-grade and most costly, followed by JGS3, then JGS2.

- Optical Coatings: AR or HR coatings can enhance performance and durability.

- Application-Specific Selection: Correct material choice is critical for optimal optical and mechanical results.

John Moncrieff Ltd provides expert consultation and processing across all fused-silica types, helping clients select the right grade and specification for every application — from deep-UV optics to infrared industrial systems.