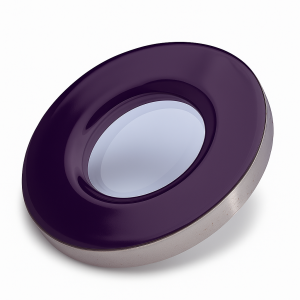

Glass-Lined Metal Fused Sight Glasses — Ultimate Safety & Chemical Resistance

Glass-lined METAGLAS® sight glasses combine the safety of mechanically pre-stressed fused glass

with the exceptional chemical and surface properties of glass-lined steel.

This hybrid design delivers unmatched durability, corrosion resistance, and process purity — making it ideal

for the most demanding environments in the chemical, pharmaceutical, and food industries.

As modern processing evolves, new materials and techniques continue to push requirements beyond what conventional

steels, plastics, and elastomers can tolerate. Glass lining — a long-established and proven technology — remains

the only material capable of delivering the combination of chemical inertness, hardness, non-diffusion, and

long-term durability required in many of these advanced applications.

Key Material Advantages

- Exceptional Corrosion Resistance: Glass enamel is virtually inert, providing outstanding protection against aggressive acids, solvents, and process media.

- Hard-Wearing Surface: Highly abrasion resistant with long service life, even under continuous duty.

- Non-Diffusive: No permeation or diffusion of product — ideal for contamination-critical processes.

- Chemically Inert: Glass lining has no catalytic effect on reactions and does not alter product purity.

- Thermal Shock & Pressure Resilience: METAGLAS® mechanical pre-stress provides superior safety performance.

Installation & Operating Conditions

For installation and operation, the general conditions applicable to glass-lined vessels also apply

to glass-lined METAGLAS® sight glasses.

This ensures full compatibility with:

- Glass-lined reactors and pressure vessels

- Glass-lined nozzles and manways

- Chemical processing and solvent handling vessels

- Pharmaceutical and specialty chemical production systems

- Food and hygiene-critical applications requiring total surface inertness

Why Choose Glass-Lined METAGLAS®?

- Superior optical clarity with zero contamination risk

- Chemical resistance unmatched by metal alloys or plastics

- Failsafe mechanical strength from fused, pre-stressed glass

- Long service life in highly corrosive or abrasive environments

- Ideal for advanced chemical, pharmaceutical, and food processes

For correct installation, specify vessel type, nozzle standard, gasket material, pressure/temperature limits,

and sealing requirements.

John Moncrieff Ltd supplies glass-lined METAGLAS® sight glasses engineered to match the operating

requirements and compliance standards of your glass-lined vessel.