High Pressure Bursting Discs

- Product Code: High Pressure Bursting Discs

High Pressure Bursting Discs

High pressure bursting discs (high pressure rupture disks) provide a robust, passive safety mechanism for protecting high-pressure systems from uncontrolled overpressure. Designed for tightness, reliability and repeatability, these discs act as a final line of defence to prevent system damage and operational downtime.

We offer two standard formats: conical (cap form) bursting discs for extreme pressures, and flat, flanged bursting discs for medium-to-high pressure environments. Each unit is manufactured using high-integrity materials matched to your required pressure range and process media.

Conical (Cap Form) Bursting Discs

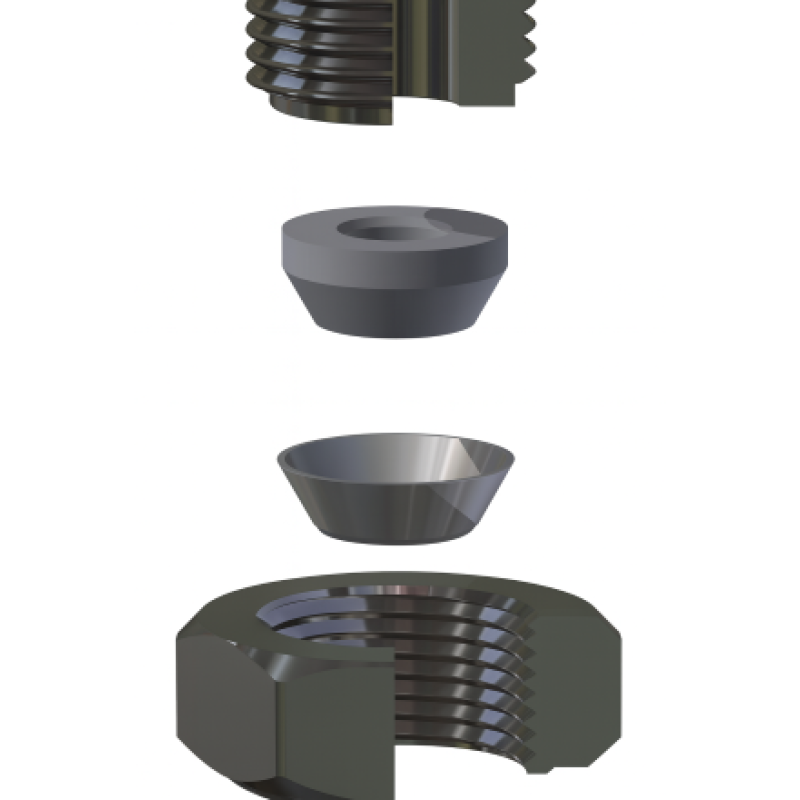

Our conical high pressure bursting discs are constructed from nickel or nickel-based alloys and engineered for operating pressures between 400 and 7,000 bar. Their cap form design works in conjunction with a cone-shaped pressure pad and a conical seat, delivering exceptional system tightness and reliable performance under extreme load.

- Pressure range: 400 – 7,000 bar

- Materials: Nickel, nickel-based alloys

- Installation: Used with cone-shaped pressure pad in conical screw connections

- Typical use: Ultra high-pressure pumps, test rigs and specialised pressure systems

Flat, Flanged High Pressure Bursting Discs

Flat, flanged bursting discs are available in nickel, stainless steel, nickel-based alloys or titanium, making them suitable for pressures below 400 bar. Installed above the pressure pad, this format offers easy access and compatibility with a wide range of high-pressure screw connections.

- Pressure range: Below 400 bar

- Materials: Nickel, stainless steel, titanium, nickel-based materials

- Installation: Positioned above pressure pad in high-pressure screw connections

- Ideal for: Medium-to-high pressure industrial systems

Applications

High pressure bursting discs (high pressure rupture disks) are widely deployed across industries where equipment protection and zero-tolerance for overpressure are operational priorities. Common applications include:

- High-pressure pumps and pump protection circuits

- Diesel high-pressure pump test benches

- Extraction systems and process equipment

- Water jet cutting plants

- General high-pressure distribution and safety systems

Custom Manufacturing & Integration

All high pressure bursting discs are produced to customer-specific dimensions and supplied with the appropriate high-pressure screw connection for either conical or flat disc formats. This ensures seamless integration, optimal sealing performance and correct burst behaviour within your system architecture.

Key Advantages

- Reliable, passive overpressure protection

- Precision performance across wide pressure ranges

- Material options to suit demanding process environments

- Extreme tightness in conical assemblies

- Reduced risk of equipment damage and expensive downtime

Designed for high-impact industrial environments, our high pressure bursting discs provide precision, durability and proven safety assurance across a broad spectrum of applications.

Technical Specifications:

Tags: high-pressure bursting disc, heavy-duty rupture disc, industrial rupture disc, over-pressure protection disc, pressure safety disc, high burst pressure disc, pressure relief device, industrial safety component, John Moncrieff, burst disc DN15–DN900, high-integrity rupture disc