Monitor of bursting disc/Transmitter

- Product Code: Monitor of bursting disc/Transmitter

Monitor of Bursting Disc / Transmitter

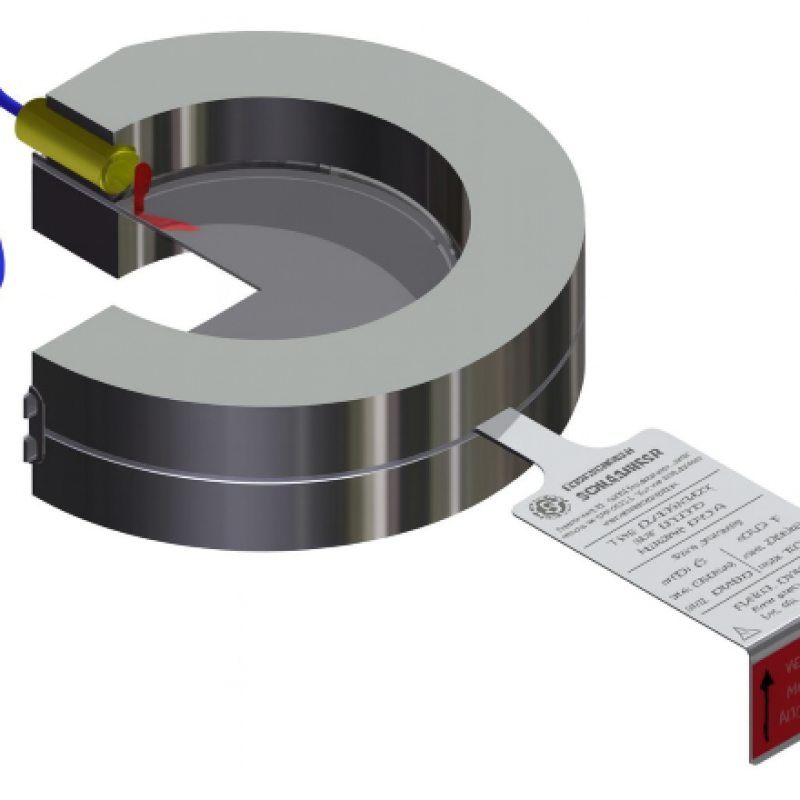

Our signal transmitter with inductive proximity switch is a highly engineered monitoring solution designed to identify bursting disc (rupture disk) activation with precision and reliability. Built for demanding industrial environments, particularly explosion-protected systems, it provides dependable rupture detection with minimal maintenance requirements.

The transmitter assembly includes an inductive sensor, proximity switch and—when specified by the customer—a compatible isolating switch amplifier. The complete unit is mounted in a holder that is clamped between two flanges, ensuring secure positioning within the system architecture.

Operation & Positioning

Accurate placement is critical for reliable signalling. The inductive proximity switch is installed at a distance of 2–4 mm from a metal lug that is fixed to the bursting disc (rupture disk). When the disc opens due to overpressure, the lug shifts position, and the proximity switch immediately registers this movement—triggering a fault signal to the process control system.

- Detection principle: Inductive sensing of lug displacement

- Switch distance: 2–4 mm from metal lug

- Installation: Mounted in a holder between flanges

- Optional: Isolating switch amplifier for hazardous areas

Maintenance Advantages

After a rupture event, only the bursting disc requires replacement. The inductive proximity switch itself remains undamaged thanks to its protected mounting position. This dramatically reduces repair and replacement costs, particularly in systems where downtime is expensive.

- Low maintenance: Switch remains intact after disc rupture

- Cost-efficient: Only the bursting disc needs replacing

- High durability: Resistant to mechanical stress during failure events

Applications

The inductive proximity switch transmitter is ideal for environments requiring precise rupture monitoring and compliance with explosion protection standards. Typical applications include:

- Explosion-protected systems and containers

- Process equipment with elevated safety requirements

- Industrial systems with operating temperatures up to 150°C

- Plants where rapid rupture notification is critical to safe operation

Compact, robust and engineered for harsh environments, our inductive proximity signal transmitter delivers accurate, real-time detection of bursting disc activation while minimising maintenance and operational costs.

Technical Specificaions:

Tags: bursting disc monitor, rupture disc monitoring, pressure safety monitor, disc failure detection, process safety device, rupture disc sensor, John Moncrieff, pressure system safety equipment, industrial safety monitor, bursting disc integrity monitor, pressure relief monitoring device